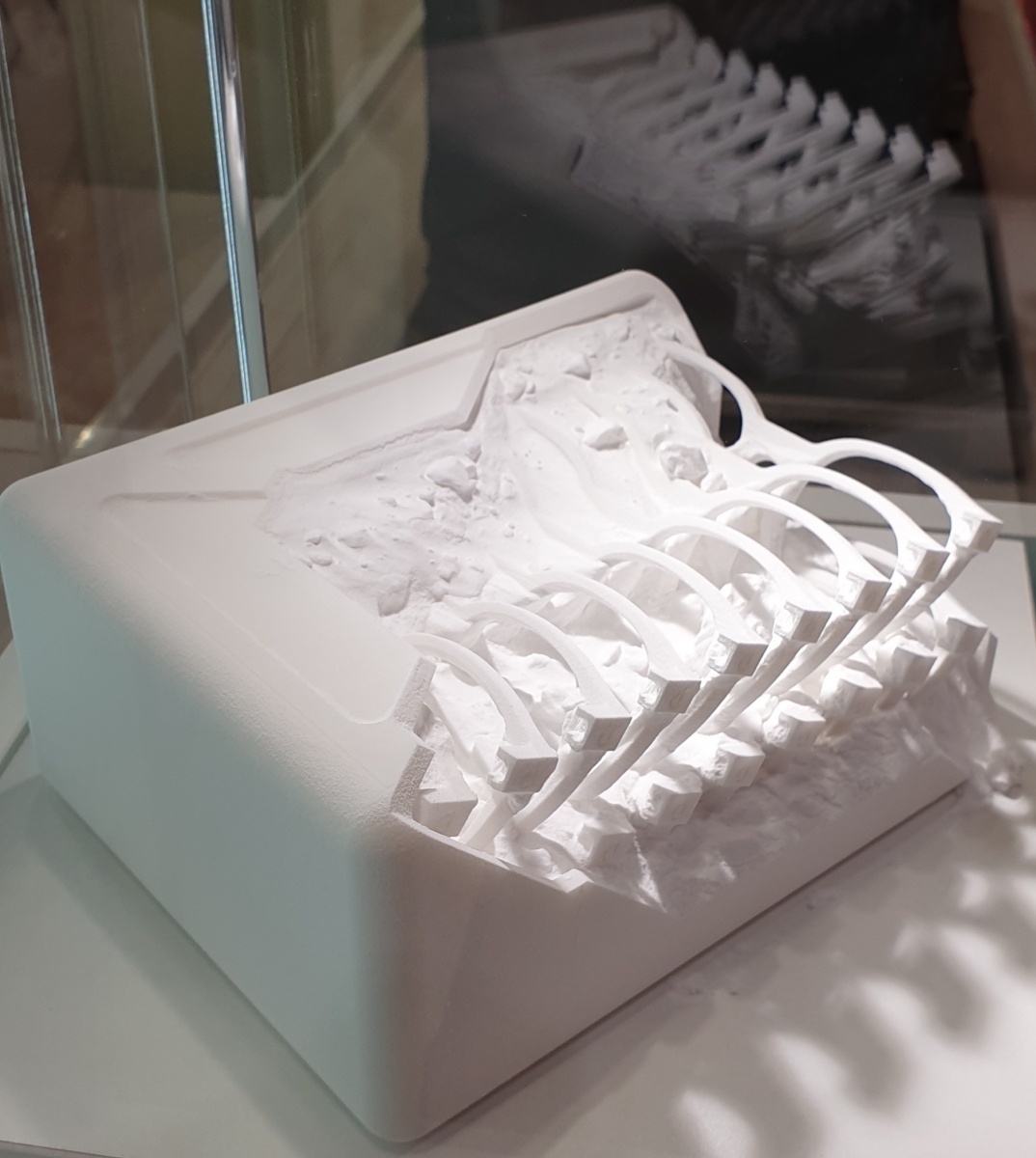

Selective Laser Sintering

First, a thin layer of the powder material is applied to the build platform. A strong laser beam melts the powder exactly where the computer-generated part design data dictates. After that, the production platform lowers and another powder application takes place. The material is melted again and combines at the defined locations with the underlying layer. Excess powder is discharged by the wiper into the two overflow tanks, which are also left and right behind the storage tanks, and can be reused after the process. The additive process of laser-sintering has existed for more than 25 years.