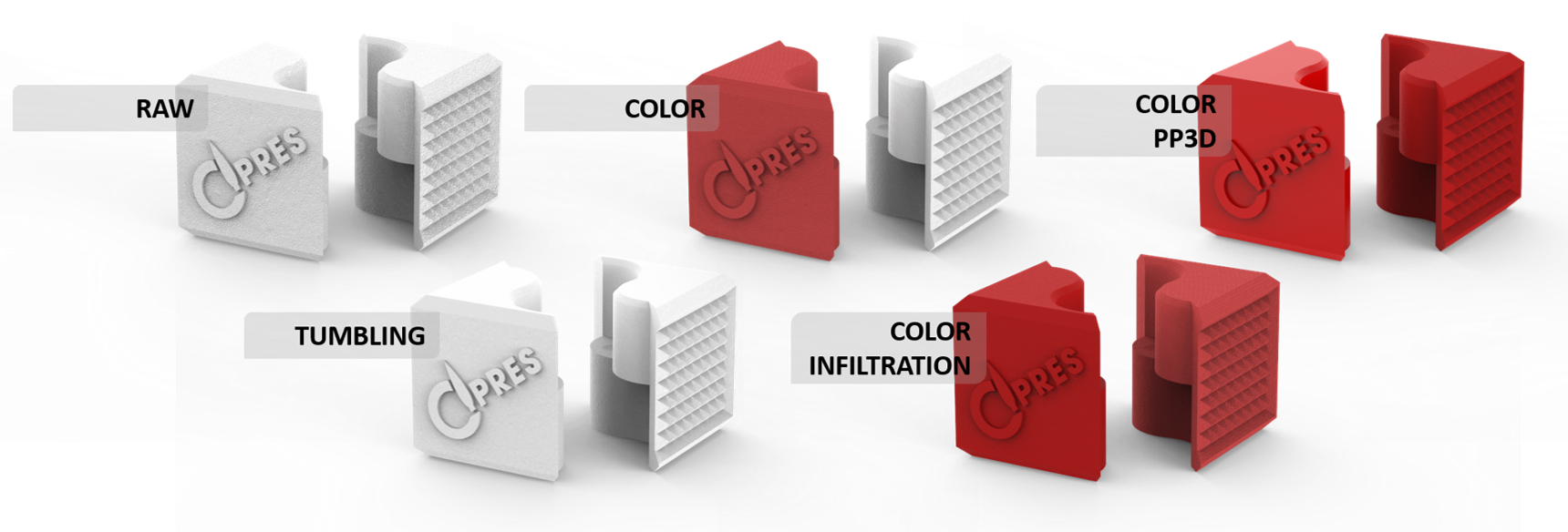

Surface finishing

So that your idea is not only implemented, but becomes a perfect series product.

Only through finishing does a 3D-printed component get its finishing touch. CIPRES has state-of-the-art high-tech machines which, by polishing, vibratory grinding, smoothing, infiltrating, dyeing, protecting, painting and brightening, turn your idea into what it should be: a perfectly manufactured series product that fulfills all functional and visual requirements.